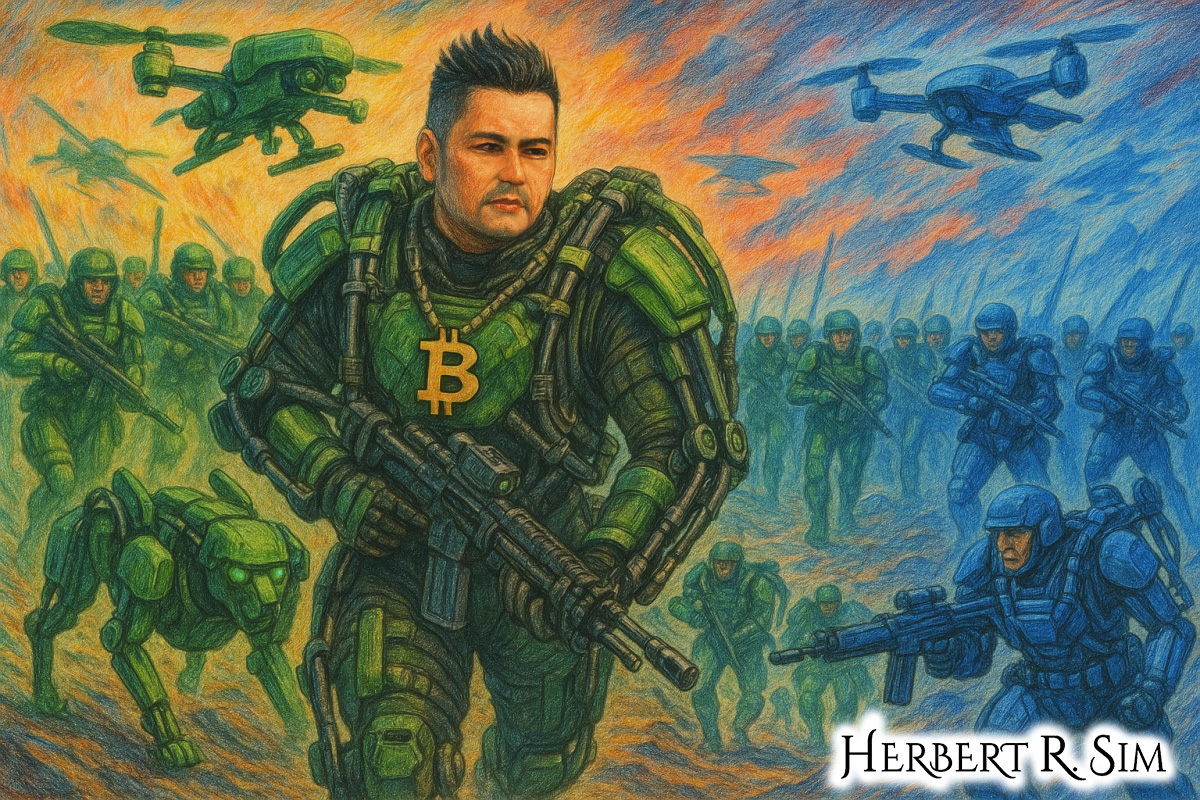

In my illustration above, I attempt to showcase how a ‘Soldier of the Future’ is equipped with Exoskeleton (inspired by ‘Edge of Tomorrow’ movie), fighting alongside with military robot dogs and drones.

For more than half a century, powered exoskeletons have flickered between laboratory curiosity and sci-fi icon. Today, they’re edging into something more consequential: a portfolio of load-bearing, mobility, and protective systems that could change how infantry move, fight, and recover.

Instead of promising “Iron Man” suits that turn troops into invulnerable superheroes, the most credible military exoskeletons now target humbler — but vital — gains: shaving metabolic cost on long marches, steadying a weapon, stabilizing a knee, or transferring the weight of an 80-pound ruck to the ground. Those incremental advantages, multiplied across squads and sustained over days, redefine endurance.

Why endurance is the center of gravity

Western infantry have never carried more. A modern soldier’s burden — body armor, batteries, water, optics, comms, extra rounds — often exceeds what doctrine says is sustainable. Fatigue degrades marksmanship, slows decision-making, and invites injury; overuse injuries can sideline as many troops as enemy action. Exoskeletons counter that spiral by offloading weight from joints to frames and by adding a “little push” at the ankle, knee, or hip exactly when the body needs it most. The U.S. Army and special operations community have invested in multiple approaches precisely because small percentage improvements compound over distance and time.

The earliest vision — full-body powered armor — proved mechanically and energetically unforgiving. Programs like Raytheon’s XOS and Lockheed’s HULC showed what a tethered, hydraulically boosted human could lift, but they also exposed the hard limits of batteries, heat, and human-machine comfort. As developers discovered, you can make a soldier incredibly strong for minutes; making them a little stronger for hours is the war-winning trick.

From hard suits to “robotic textiles”

The field’s most important pivot has been from rigid, load-path exoskeletons to “soft” exosuits — garments and cable-driven braces that add assistance without encasing limbs in aluminum. Harvard Wyss Institute–inspired designs and their commercial spinoffs demonstrated repeatable reductions in metabolic cost: single-digit percentages that matter when you’re climbing a hill under a pack. Unlike earlier frames, soft suits distribute forces with textiles and small actuators, minimizing interference with gait and range of motion.

This evolution shows up in military-adjacent products as well: industrial exoskeletons for auto and aerospace workers, and “exo-shorts” or hip-assist devices that blur the line between brace and robot. That cross-pollination accelerates the parts of the tech stack defense buyers struggle with most — comfort, reliability, maintainability — while industry and rehab markets help drive cost down.

Load-bearing: making 80 pounds feel like 60

Leg-dominant systems focus on what infantry feel first: quadriceps and calf fatigue. Lockheed’s lower-body FORTIS/ONYX lineage routes tool or pack weight to the ground and times knee torque to the user’s gait, easing the worst phases of climb and descent. Rigid or semi-rigid frames still matter for heavy tools or stretcher duty; soft suits excel when you need assistance but also need to crawl, kneel, or go prone. In both cases, the goal is not super strength but net-positive endurance — arriving less spent and more stable.

Beyond the legs, “third-arm” concepts and shoulder-assist rigs redistribute the mass of machine guns, breaching tools, or anti-armor systems from the arms to the body’s core. Even modest stabilization translates to steadier sights and slower fatigue in protracted engagements. The principle is simple ergonomics, mechanized.

Rigid, full-body suits haven’t vanished. France’s RB3D “Hercule” and similar frames framed the early promise: 200-plus pounds of assisted carry, servo-mirrored to the wearer’s movement. They remain instructive testbeds for load paths and joint alignment — knowledge now embedded in more agile designs.

Mobility: shaving metabolic cost and smoothing movement

The mobility story is increasingly quantitative. In repeated studies and product demos, exosuits can reduce the energy required to walk or run with a load by several percent. That sounds small until you’ve covered 20 kilometers; then it’s the difference between a squad hitting the objective ready to fight or needing a breather they won’t get. Academic-industry teams have pushed controllers that “learn” a user’s gait and adjust assistance timing in real time, underscoring that software — anticipation, not just amplification — is the secret sauce.

Weapon handling and micro-stability are part of mobility, too. Early Army research explored exoskeletal stabilizers to dampen tremor and recoil — think Steadicam for marksmanship — illustrating how precision can be an endurance effect. If a device slows your fatigue curve, you take better shots deeper into a fight.

Protection: the TALOS lesson

If there’s one cautionary tale every exoskeleton engineer knows, it’s SOCOM’s TALOS suit — an ambitious push to integrate powered armor, climate control, sensors, and comms into a single “operator skin.” TALOS advanced materials, thermal management, and human-systems integration, but it also showed how complexity and power draw explode when you try to do everything at once. The program’s most enduring impact may be cultural: it nudged the community from moonshots to modules. Today’s protective ambition favors better plate carriers, micro-climate layers, and exo-assists you can don like kit, not an all-or-nothing shell.

This modular ethos mirrors a broader military shift: do what the battery can pay for. Optics and radios already compete for watts; adding motors raises the stakes. Designers who deliver “just-enough” torque exactly when it’s biomechanically valuable win. Those who demand constant peak power lose to physics — and logistics.

The global and industrial spillover

Not all exoskeleton momentum comes from defense. Auto, aerospace, and logistics firms deploy passive shoulder frames and back-assist harnesses to reduce injury and boost throughput, a trend that matters to armies because the same vendors iterate at industrial scale. Ottobock’s Paexo, Ford’s assembly-line trials with Ekso, and other shop-floor deployments widen the supplier base and normalize maintenance patterns — practicalities that often decide what survives fielding.

Meanwhile, defense primes and startups have learned hard lessons from earlier cycles. Lockheed’s HULC dazzled a decade ago; today, the same shop markets subtler ONYX-class aids and software. Media fascination with “power armor” lingers, but the market votes for devices that slip under uniforms, not over them.

The ethics — and hype — check

Popular culture primes us to expect cinematic suits. Journalism and policy voices have long warned about overpromising and underpowering, with battery life, heat, and human factors the usual culprits. Those critiques were right — and they helped push the field toward realistic, testable, soldier-centered wins. On the ethics side, scholars have cautioned that even benign-seeming augmentation changes norms of risk, consent, and “returning” a soldier to baseline after service, concerns militaries must fold into doctrine and medical support.

Where exoskeletons fit in tomorrow’s platoon

So what does a credible 2030s exoskeleton stack look like? Think ensemble:

- Lower-body assist for marches and hills, tuned to gait and terrain, with duty cycles measured in patrol hours.

- Shoulder/arm offloading for heavy weapons and breaching, attachable when mission dictates.

- Micro-stabilization for marksmanship and for casualty movement, including powered lift aids to spare backs under stress.

- Soft-layer climate and posture management, to reduce heat stress and repetitive-strain injuries in armor.

Crucially, these are not standalone silver bullets; they’re wearables that complement drones, sensors, and lighter armor — one more way to tilt the balance toward alert, uninjured, decisive humans at the point of contact.

The bottom line: endurance beats spectacle

The soldier of the future will look much like today’s — boots, rifle, plates — until you look closely and watch them move. Their steps will be a little easier, their knees a little fresher on the last climb, their posture a little steadier under a crew-served weapon, their core a little cooler under the sun. That’s what exoskeletons, in their most useful form, buy you: endurance, preserved and extended. It’s not as cinematic as a man in a flying suit. It’s more valuable.