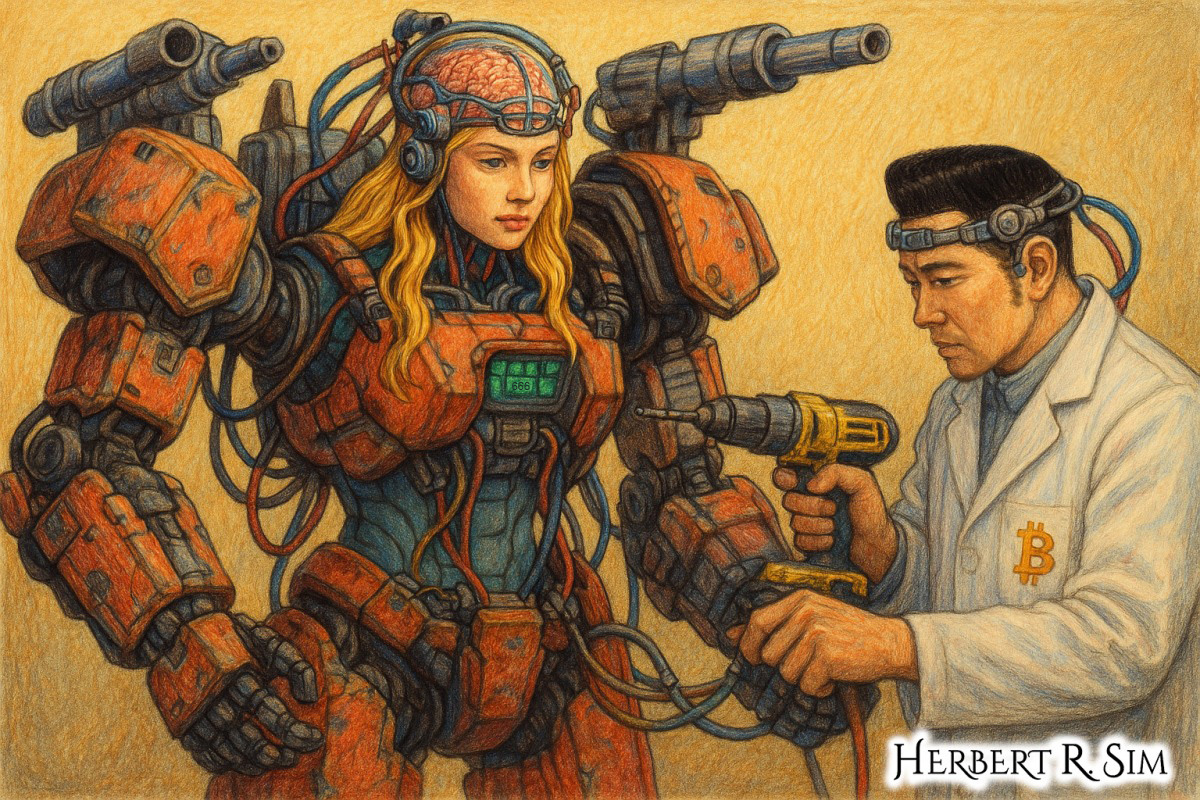

In my illustration above, I feature a lady wearing a military exoskeleton inspired by the movie Avatar (2009) – Amplified Mobility Platform (AMP) suit, but in cyborg bionic style, and powered with brain-computer interface aka Neurochip with her brain visible.

Walk into any lab, clinic, or defense expo in the early 2010s and you’d see two very different species of “wearable robots” evolving in parallel. One lineage — rigid, power-dense exoskeletons — wrapped people in aluminum and carbon-fiber frames to multiply strength or restore gait.

The other, newer lineage pointed to soft, compliant “exosuits” and passive assist devices that promised comfort, safety, and long wear — sometimes without a single motor. Both paradigms were already on display before today, and both foreshadowed where wearable robotics would go next.

What we mean by “hard” vs. “soft”

Hard (rigid) exoskeletons use external frames and rigid joints with actuators (motors or hydraulics) to add torque directly at hips, knees, or shoulders. Think Lockheed Martin’s HULC (Human Universal Load Carrier) or Raytheon’s XOS2, designed to move heavy loads, reduce injury, and extend endurance. In demonstrations around 2010–2011, soldiers squatted, climbed, and hefted steel plates with almost cinematic effortlessness — while engineers measured metabolic cost, gait, and control.

Soft exosuits, by contrast, distribute forces through fabrics, springs, elastic tendons, or lightweight linkages. Some are passive — no motors, just clever mechanics that offload repetitive strain (e.g., arm-support devices for factory work). Others borrow ideas from the emerging field of soft robotics, which uses elastomers and “jamming” structures to create compliant, adaptable motion without heavy joints — pointing to future wearables that feel more like clothing than armor.

Use cases where rigid shines

Heavy lifting and military logistics

Hard suits excel at load transfer — routing backpack and payload forces through an external frame into the ground. That’s the core promise of HULC and XOS2: reduce joint strain, keep mobility, and sustain high workloads. Videos from the period show powered squats, crawls, and obstacle navigation; the U.S. Army’s testers emphasized not just strength but energy use, speed variation, and stability under a shifting ruck.

At trade shows and demos, rigid frames also “walked the floor” and mingled with attendees — signaling maturing control software and power management. These early public performances mattered because they moved exos from lab curiosities toward field trials with soldiers and contractors.

Clinical gait restoration and rehab

In clinics, rigid lower-limb systems like eLEGS/Ekso and ReWalk did something profound: they let some paraplegic users stand and walk — with supervision — often for the first time since injury. Early features included crutch-mounted controls, onboard computers, and sensor arrays; clinical partners evaluated oxygen uptake, muscle activity, and broader health markers from upright mobility. Stories of students walking at graduation and pilot rehab trials at Kessler and other centers brought these devices into the mainstream.

The HAL (Hybrid Assistive Limb) suit from Cyberdyne showed yet another control modality — bioelectric signals on the skin that let the frame “read” intent and amplify it. Early U.S. demos at CES 2011 and coverage in The Economist framed HAL as “robotic trousers” for paraplegics — a vivid metaphor for how close the hardware sat to the body.

Industrial ergonomics and endurance

Rigid frames weren’t just for soldiers and patients. By 2011, factories were eyeing exos for repetitive overhead work and injury prevention. Even Honda explored walking-assist devices to take stress off hips and knees, hinting at industrial and eldercare crossover.

Bottom line: Rigid exos are the go-to when you need high, precisely delivered joint torques, strong load paths, and controlled, repeatable motion — especially in supervised settings.

Where soft exosuits (and passive aids) lead

Comfort, compliance, and long wear

Soft systems trade raw torque for comfort, safety, and wearability. The x-Ar forearm support (2011) illustrated the concept: a light, body-mounted linkage that counterbalanced the arm, offloading shoulder and neck strain during repetitive tasks — no motors required. This is the sweet spot for soft/ passive aids: reduce fatigue and cumulative trauma disorders by supporting posture and limb weight, not by overpowering the body.

The soft robotics thread

Parallel to wearables, DARPA-backed research pushed elastomeric “chembots” and jamming-based structures that can toggle between soft and firm, crawl, or squeeze under obstacles. While not exosuits per se, they seeded materials and actuation ideas — compliant skins, distributed pressure actuation, friction-tuned interfaces — that would later filter into wearable textiles and soft braces. Think of it as a materials and mechanisms pipeline for future soft exosuits.

Early, low-mass mobility aids

Even within “rigid” brands, you can see the soft-ward drift pre-2012: lighter frames, smarter control that relies on the user’s own balance (lean-forward to step; lean-back to stop), and a design priority on fit and comfort in rehab contexts. Those HMI patterns — gentle intent sensing, minimal encumbrance — map directly to soft exosuit philosophy.

Bottom line: Soft/ passive systems prioritize compliance and human-in-the-loop comfort. They aim to be worn longer and safer, particularly in factories, logistics, and assistive daily living — domains where bulk, batteries, and hard joints can be deal-breakers.

Trade-offs that matter

- Power & Payload vs. Comfort & Safety

Rigid wins on peak assistance (stairs with a load, floor-to-stand transfers); soft wins on wear time and low risk in crowded, real-world spaces. Rigid frames can pinch or misalign; soft garments spread forces across fabric and belts. - Control Architecture

Early HAL systems read bioelectric intent and drove motors; Ekso and ReWalk mixed sensor triggers with therapist supervision. Soft devices often embed human biomechanics as the controller — springs and linkages provide help when and only when muscles get tired. - Energy & Runtime

Batteries and hydraulics limit day-long use for rigid suits; soft devices may be battery-free or sip power, making shift-length wear feasible. (That’s why passive arm/shoulder supports gained early industrial interest.) - Regulatory & Clinical Pathways

Medical exoskeletons must show reliable, repeatable outcomes in rehab trials (oxygen uptake changes, EMG signals, pressure relief from upright posture). Rigid systems led the first wave of such studies pre-2012. Soft devices faced less stringent paths if marketed as ergonomic aids, not medical devices. - Cost & Access

In 2010–2012, powered suits were expensive (early clinic-only deployments and lease models); soft aids and passive frames tended to be cheaper and simpler to deploy. Public demos — from a paralyzed student walking at graduation to clinic pilot programs — accelerated visibility but also highlighted cost gaps between rigid clinical gear and lighter workplace aids.

How the early 2010s shaped expectations

Media from 2010-2012 painted a vivid, sometimes contradictory picture. On one hand, “Iron Man”-style strength drove defense hype cycles; on the other, rehab miracles — students and patients walking — showed immediate human impact.

The Economist’s “right trousers” framed wearable robotics as dignity-restoring tools as much as super-strength machines. That period also surfaced real constraints: supervision needs, cost, battery life, and questions about where wearables fit in everyday life.

Meanwhile, reporting on brain-machine interfaces hinted at a future where intent flows straight from cortex to suit — useful for users without strong residual signals. Even then, coverage emphasized how gait safety, fall risk, and real-world tasks would matter more than lab heroics.

Practical guidance: choosing the right tool

-

- Military logistics / disaster response: Pick rigid frames when the job demands measurable joint torque and load carriage over uneven terrain, with trained users and safety protocols.

- In-clinic gait therapy: Rigid medical exoskeletons provide structured, repeatable therapy sessions with therapist oversight, documented in early trials.

- Light-industry ergonomics (assembly, overhead tasks): Favor soft/passive supports first; they improve endurance and reduce musculoskeletal strain without power or complex training.

- Daily living assistance: Lightweight, comfortable systems (including minimal, soft components) that respect natural balance cues are more likely to be adopted than bulky frames — especially outside supervised environments.

The synthesis we were headed toward — even then

By 2012, the trajectory was clear: the future would blend the two. Rigid devices were already getting lighter and smarter, while soft systems were adding sensing and actuation concepts from soft robotics. The Verge’s pre-2012 coverage of Ekso demos and HAL variants illustrated that drift: industrial design partnerships, intent-sensing controls, and the search for comfort beyond the lab.

Hard exos will keep owning high-assist, high-load niches; soft exosuits and passive aids will win comfort-first tasks — and the vast middle ground will borrow liberally from both. That was the bet the field made up-to-date, and it remains the most likely synthesis going forward.