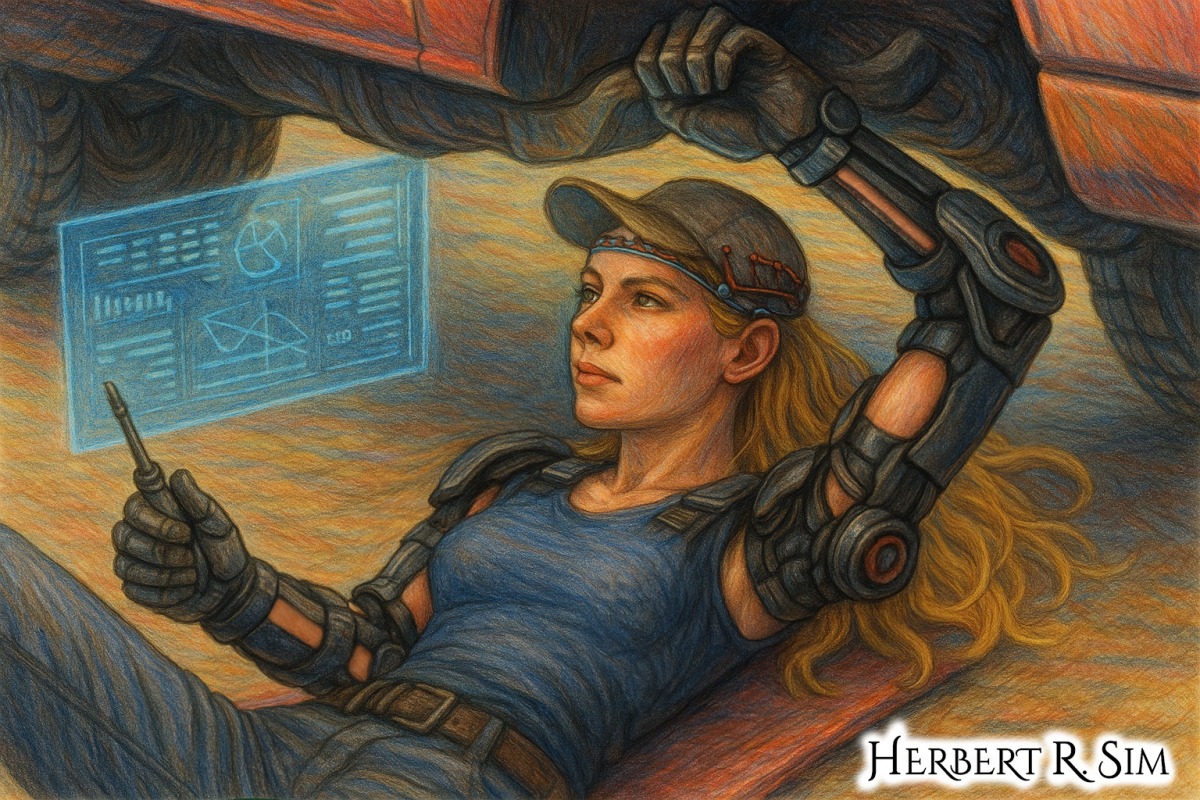

In my illustration above, featuring a female mechanic equipped with exoskeleton mechanical arms that enables her to have superhuman strength.

Exoskeletons — once the stuff of comics and summer blockbusters — have spent the past decade edging out of labs and trade-show booths into rehab clinics, factories, and even marathons. But “edging” is the operative word. For most households, powered suits remain aspirational: captivating demos, steep price tags.

So what will it take for exosuits to cross the chasm from showcase tech to something that belongs in homes, garages, and closets — like a high-end e-bike or treadmill? To answer that, it helps to trace how prices are set today, what manufacturing and regulatory bottlenecks look like, and where scale might finally unlock everyday affordability.

How we got here (and what it cost)

In the early 2010s, a flurry of prototypes framed the price conversation. On the medical side, Ekso Bionics rolled its battery-powered walking system into rehab centers; The Atlantic noted those first commercial deliveries in early 2012, signaling a shift from lab gear to billable equipment. Around the same time, The Verge reported that Ekso’s team openly targeted eventual consumer-level pricing of $30,000–$50,000 — ambitious, but still far from mass-market territory. Meanwhile, Britain saw headline-making demonstrations with price tags that hovered near £100,000, underscoring how far the category had to travel.

Industrial and defense prototypes weren’t cheaper. Wired chronicled the parade of militarized suits — Raytheon’s XOS 2 and Lockheed’s HULC — highlighting power, payload, and ruggedization rather than cost control, which tells you why these projects rarely translate directly into home-use devices. Those early units were built in ones and tens, with aerospace-grade components and hand-fit assemblies. That’s spectacular for performance and reliability — and brutal for price.

Even the “lightweight” industrial exos, like France’s RB3D Hercule, showed the same pattern: impressive lift assistance, low production volume, high component costs. For households, the meaningful signal wasn’t the sticker; it was the engineering trajectory — motors, sensors, and batteries were all riding broader consumer-electronics cost curves. The question has always been when (not whether) those curves intersect an acceptable price for home users.

What sets today’s price floor

- Motors, batteries, and structural materials. Exoskeletons are mechatronic systems whose cost drivers mirror e-bikes and drones, but with tighter safety and reliability needs. Actuators must deliver high torque with low weight; the gearboxes must be efficient and quiet; battery packs must be both energy-dense and medically trustworthy. In 2011–2012, most powered suits relied on custom or heavily modified components, which pushed unit costs up and slowed iteration cycles. Publications covering Cyberdyne’s HAL — demonstrated at CES and even adapted for Fukushima cleanup — captured how much bespoke design lived inside these early models.

- Software and sensors. Gait detection, fall mitigation, and seamless assist are software problems as much as hardware problems. Early reports from Engadget and The Verge emphasized how these systems depended on multi-sensor fusion and supervisory control (often via a therapist’s remote), adding development cost that doesn’t disappear just because hardware prices fall.

- Certification and care pathways. Getting a device into a hospital is different from getting it into a home. Medical-grade devices faced rigorous regulatory hurdles and long validation timelines in the early 2010s. IEEE Spectrum’s coverage from that period shows the tedious “hundreds of thousands of steps” testing mindset regulators demanded — time-consuming processes that amortize poorly over small volumes.

- Low volumes. Finally, and most importantly, low production volumes keep bill-of-materials costs high, limit supplier discounts, and make automation uneconomical. A clinic-only market sells dozens or hundreds of units per year, not tens of thousands. That volume reality is the biggest single reason prices didn’t plummet as quickly as enthusiasts predicted. You can see hints of this in 2012–2013 reporting that framed clinic sales as the primary channel, not direct-to-consumer.

Where scale could come from

Industrial and workplace safety use. Before households, the most natural “bridge market” is the workplace: logistics, manufacturing, and construction. When an exosuit reduces worker injury or increases throughput, employers can justify five-figure purchases — priming supplier volumes and maturing supply chains. Europe’s Robo-mate concept and The Verge’s reporting on factory-aid exoskeletons showed how consortia and automakers evaluated these suits to prevent injuries, not create superhumans. The more these systems sell to businesses, the more learning curves (experience curves) can kick in for the components shared with consumer models.

Soft exosuits and modularity. Reducing cost isn’t just about better deals on motors; it’s also about needing fewer of them. Passive or quasi-passive designs — think spring-assisted shoulders, unpowered hip braces with tuned damping — slash the electronics bill and rely on textiles and molded composites instead of milled metal. Even in early-2010s coverage, you can see this shift: devices like x-Ar for repetitive-strain mitigation hinted at simpler, cheaper modules that help with specific tasks. A modular, upgradeable family — ankle assist today, powered knees tomorrow — lets households buy in stages.

Rehab-to-home transitions. Rehab clinics are the proving ground: people try a device under supervision, insurers and clinicians gather outcomes, and — eventually — patients want home access. Media coverage through 2012 shows this loop clearly: paralyzed users training with clinic systems (Ekso, ReWalk) and achieving milestone activities like walking across a stage or even completing a marathon. If vendors package home units as part of a “therapy continuum” with financing, maintenance, and remote monitoring baked in, unit volumes can rise beyond the narrow clinic market.

Consumer-adjacent applications. Finally, expect early consumer adoption in hobbyist and assistive-fitness niches — hiking with load assistance, home mobility aids for aging users, or DIY maker upgrades to commercial passive frames. These niches tolerate some bulk and tinkering in exchange for meaningful capability — exactly the dynamic that carried 3D printers and drones from clubs to closets. Reporting from The Atlantic and The Verge in 2011–2012 captured how quickly demos sparked interest outside hospitals.

The affordability timeline (and what must change)

Short term — “prosumer” prices (high four to low five figures). In the near term, the realistic path to affordability looks like e-cargo bikes: $4,000–$10,000 for well-designed passive or hybrid-assist exosuits focused on a narrow set of tasks (lifting, standing, stairs). These products minimize expensive actuation; they lean on clever mechanics and textile engineering. The crucial enablers are standardized sizes (reducing custom fitting costs) and modular SKUs that keep inventories sane. Industrial pilot programs — well-documented by outlets tracking factory trials — seed the supply base and production know-how that consumer variants can leverage.

Medium term — true home mobility aids (mid four to low five figures, financed). To get powered walking aids into homes at a few hundred dollars per month (financed), vendors will need three breakthroughs:

- Commodity actuators and batteries with medical-grade reliability. As IEEE Spectrum’s early reporting shows, the first generation relied on bespoke hardware; swapping in auto-scale motors and cells (where appropriate) will cut costs dramatically.

- Proven fall-prevention and supervision. The software work is non-negotiable: safe autonomy for balance and stumble recovery. Early devices often required a therapist’s remote; home users need trustworthy, on-device safeguards. The sooner those routines are validated in clinics and codified in standards, the sooner manufacturers can ship simpler, less supervised systems for the home.

- Service models instead of sales. A household doesn’t want to own liability; it wants uptime. Expect subscription bundles — maintenance, periodic fitting, and remote telemetry — patterned after CPAP, insulin pumps, or connected fitness equipment. Early 2010s clinic deployments laid the groundwork for these service mindsets; scaling them to home use is the next step.

Long term — appliance-like prices (low four figures). The road to a $2,000–$3,000 general-purpose home exosuit runs through soft robotics (textiles, inflatable structures), high-volume molding, and ruthless simplification of electronics. In that scenario, power-assist is targeted (only where biomechanics demand it), and everything else is passive. You can already see the concept’s roots in early workplace-assist and arm-assist devices.

Lessons from the first decade of demos

The earliest widely covered exoskeletons were over-engineered for consumer price points — and they had to be. Military units had to survive sand and shock; clinic hardware had to be safe, repeatable, and serviceable; Fukushima-era deployments had to integrate with protective gear. Those constraints make for inspiring videos and crucial learning, not cheap bill-of-materials. Wired’s snapshots of HULC and XOS 2, and The Verge’s reporting on HAL’s radiation-cleanup variant, read like case studies in performance at all costs. The consumer playbook is different: pick the smallest useful problem, minimize motors, and sell thousands, not dozens.

Media also documented a steady expansion of use cases — paralyzed students walking at graduation, marathon finishes in robotic legs, industrial prototypes hoisting heavy loads. Those stories matter economically because each one grows the addressable market and normalizes the product. The more ordinary these devices feel, the easier it becomes to finance them, insure them, and sell them through conventional retail and clinical channels.

What has to happen next

- Common form factors. Standardizing mounting points, battery packs, and control interfaces lets third-party suppliers emerge — historically the biggest lever in price reductions for complex consumer devices. Early-2010s systems were mostly closed; the next wave should look more like PCs and e-bikes (lots of interchangeable parts), not like bespoke medical appliances. Reporting from that era shows how custom everything used to be — ripe for modularity now.

- Regulatory clarity for home use. Clear, tiered device classes (passive assist vs. powered mobility aid) reduce friction and shorten time-to-market. The clinic-first path documented by Spectrum and The Atlantic was sensible; moving beyond it will require harmonized standards that acknowledge different risk profiles in the home.

- Evidence of outcomes beyond “wow”. It isn’t enough to stand up and take a few steps. Health-economic data — reduced secondary complications, fewer falls, better independence — will justify coverage decisions and financing tools. Early mainstream coverage focused (understandably) on milestones and demos; the next phase must quantify durable benefits.

- A credible “good-enough” tier. Affordable exosuits won’t match lab-grade devices on every metric — and don’t need to. If a $4,000 system helps a parent carry a toddler upstairs safely every day, that’s a winning product. The 2011–2012 wave of simpler arm and shoulder assists hinted at this future: narrow tasks, big impact, acceptable price.

So…when do households get in?

If you define “affordable” as the price of a quality e-cargo bike or home treadmill, the first broadly useful home exosuits look achievable when two conditions converge: (1) passive and quasi-passive designs for specific tasks mature through workplace deployments, and (2) powered modules for mobility migrate from clinic-monitored devices to supervised home use with robust fall-handling.

Given the trajectories documented in 2011–2012 — clinic deliveries, industrial pilots, and component cost declines — it’s reasonable to expect consumer-adjacent prices on targeted devices first (lifts, stairs, standing aids), with full powered gait systems following as safety software and financing models catch up. The gloss of the early demos was never the endgame; it was the apprenticeship.